Brief introduction:

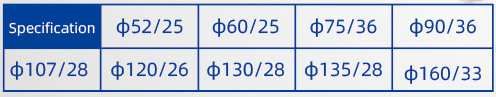

Parallel Twin Screw&Barrel

Basic parameters:

Product category: corotating bon-screw & barrel,

counter-rotating parallel twin-screw & barrel

Surface processing technology: nitriding, alloy spraying,

Chrome Plating, etc.

Nitriding hardness HV: 860-980

Straightness: 0.05mm Surface finish Ra :Ra≤0.2

Scope of application:

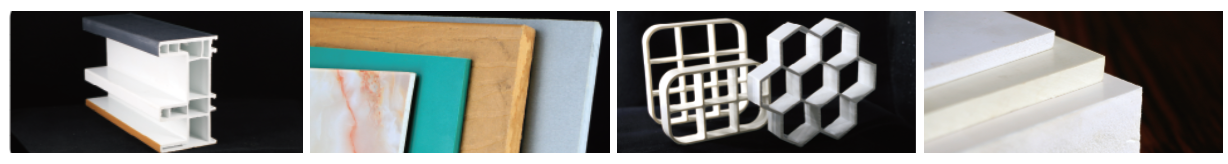

It is suitable for extrusion of PVC pipes, profiles and sheet foam products.

It is suitable for CPVC pipe extrusion.

Composition and process:

Screw

Produced with High-quality 38CrMoALA or 1.8550 forging material, with quenching and tempering to HV290-320, flight surface made with nickel alloy plasma welding, alloy thickness≥1.7mm, hardness≥HRC58, nitriding by NITREX process after finishing machine, nitriding depth: 0.5-0.7mm, hardness: HV860-980, grade 2 metallographic structure or above.

Barrel

The barrel is made of high-quality 38CrMoALA forging material, after quenching and tempering to HB290-320, nitriding with NITREX furnace process after finishing machine, the nitriding depth is 0.5-0.7 mm, the hardness is HV860-980, with grade 2 metallographic structure or above.

The barrel is designed as “detachable”, 42CrMo barrel is quenched and tempered to hardness HB290-320, inlaid with German HPT1 alloy sleeve. The thickness of the alloy is more than 7 mm, the hardness is HRC58-62, the shell of the barrel can be used, and the inner alloy sleeve can be replaced after wear out.